Comprehensive Guide to Heavy-Duty 2500/3500 Pickup Trucks: Features, Performance, and Comparison

Introduction and Outline: Why Heavy-Duty 2500/3500 Pickups Matter

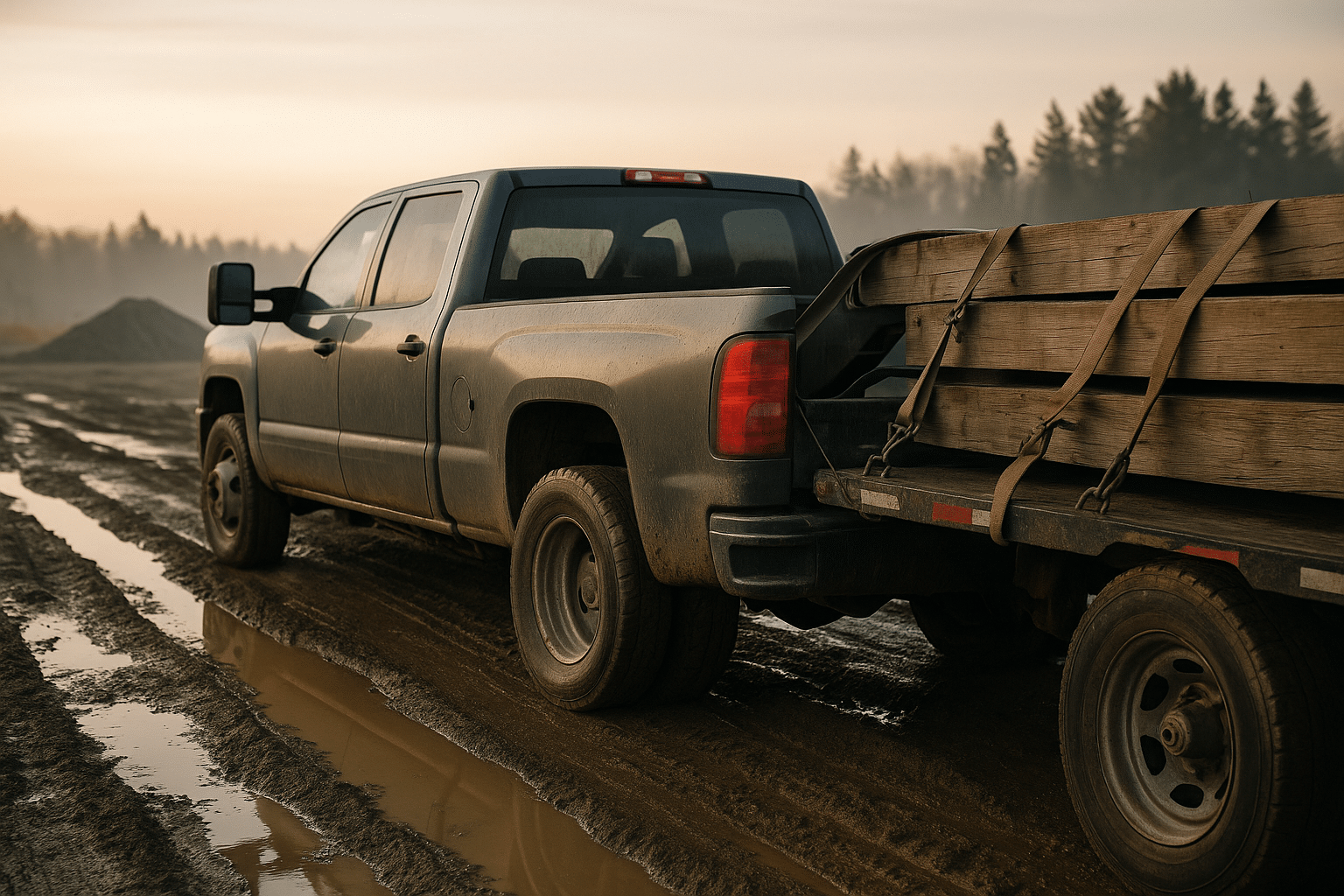

Heavy-duty pickups in the 2500 and 3500 classes sit at the crossroads of utility and everyday usability. They haul equipment across muddy job sites, tow multi-axle trailers over mountain passes, and still squeeze into a grocery store lot when the day is done. For contractors, ranchers, fleet managers, and serious recreational towers, these trucks are more than transportation; they are rolling toolsheds, mobile powerplants, and a reliable lifeline when deadlines and weather turn unforgiving. Choosing the right configuration can transform a long workday into an efficient, predictable routine, while the wrong choice can saddle you with costly downtime and frustrating compromises.

This article unpacks how these machines are classified and what their numbers actually mean, then moves through the practical steps required to build a work-ready specification. From engine and axle decisions to upfit planning and safety technology, we translate spec sheets into plain language. You will also find ownership considerations that go beyond the sticker price, helping you weigh fuel, maintenance, compliance, and resale value against the realities of your workload.

Outline of the article:

– Overview of 2500/3500 classes: GVWR, payload, towing, bed and cab choices, and the role of single vs. dual rear wheels

– Specifying a work truck: payload math, hitch types, chassis cab vs. pickup, upfit options, and job-based configurations

– Performance and durability: engines, transmissions, cooling, brakes, suspension, and traction systems that actually endure heavy cycles

– Ownership and safety: real-world fuel consumption, maintenance schedules, driver-assist features, and regulatory triggers

– Actionable conclusion: decision checklist to help you choose between 2500 and 3500 setups with confidence

Whether you manage a fleet or purchase a single truck for a small business, the goal is the same: select a configuration that aligns with your loads, terrain, and duty cycle. We will show how to read the capacity labels, how to predict real-world performance, and where seemingly small choices—like axle ratio or tire load rating—can have outsized effects on capability and cost. Think of what follows as a field guide: practical, data-informed, and grounded in the work these trucks do every day.

Heavy-Duty 2500/3500 Pickup Truck Overview

In North America, heavy-duty pickups commonly align with vehicle classes based on Gross Vehicle Weight Rating (GVWR). A 2500 model typically falls into Class 2b (about 8,501 to 10,000 pounds GVWR), while a 3500 version generally lands in Class 3 (10,001 to 14,000 pounds GVWR). That jump may look modest on paper, but it changes the entire truck: frame reinforcements, axle capacities, springs, brakes, wheel and tire ratings, and often the availability of dual rear wheels. Those structural differences ripple through payload and towing numbers, stability under load, and durability across long service lives.

Payload illustrates the spread. Many 2500s deliver roughly 2,000 to 4,000 pounds of payload depending on cab, bed, engine, and options. A 3500 can push beyond that, with single-rear-wheel versions often in the 3,000 to 5,000-pound neighborhood and dual-rear-wheel configurations reaching significantly higher figures when properly equipped. Towing follows suit. Conventional (bumper-pull) tow ratings for these trucks typically range from the mid-teens to around 20,000 pounds, while fifth-wheel and gooseneck setups can stretch into the low 30,000-pound range on certain dual-rear-wheel configurations, subject to the manufacturer’s published limits and the trailer hardware used. Standardized rating methods such as SAE J2807 help align these figures to real test protocols, but the final word is always the door-jamb sticker and the specific build.

Powertrains are equally varied. Gasoline engines appeal for lower upfront cost, simple emissions hardware, and strong high-rpm power, making them appealing for mixed-use fleets and shorter trips. Modern turbo-diesel engines trade higher purchase price for abundant low-rpm torque—often in the 700 to 1,000 lb-ft range—ideal for long grades, heavy trailers, and high-altitude work. Transmission choices typically span robust multi-speed automatics, with tow/haul modes and smart shift mapping to manage heat and engine braking on descents. Cooling packages, alternator output, battery capacity, and axle ratios complete the spec picture; together, they determine how the truck feels once it’s loaded and rolling.

Cab and bed combinations shape utility and weight. Regular cabs maximize payload and cost-efficiency, extended cabs add storage and occasional seating, and crew cabs prioritize passenger space. Bed lengths usually center around six-and-a-half or eight feet, with factory provisions for fifth-wheel/gooseneck hitches available on many heavy-duty trims. Dual rear wheels—common on 3500 models—deliver extra stability and payload headroom, especially helpful in crosswinds or when towing tall, heavy trailers. Add it all up and the picture is clear: the 2500 strikes a balance for daily driving and moderate towing, while the 3500 targets heavier payloads, frequent towing, and maximum stability under demanding conditions.

Specifying a Work Truck: Fit-for-Purpose Choices

Spec’ing a heavy-duty work truck starts with a candid look at your job’s demands. Before shopping options, define the heaviest loads, the steepest grades, and the roughest surfaces you expect to encounter. Then match the truck to that reality, not the other way around. The foundation is weight math: Payload equals GVWR minus curb weight minus passengers and gear, and it must also cover upfit components like service bodies, cranes, ladder racks, toolboxes, or fuel transfer tanks. For trailering, reference Gross Combined Weight Rating (GCWR); maximum trailer weight is GCWR minus the actual loaded weight of your truck. Tongue weight targets typically run 10 to 15 percent of trailer weight for conventional hitches and roughly 15 to 25 percent for fifth-wheel or gooseneck hitches. If you exceed payload via tongue or pin weight, capability collapses—even if a brochure tow number looks generous.

One of the first forks in the road is pickup bed versus chassis cab. A pickup with an eight-foot bed and a factory fifth-wheel/gooseneck prep can be a versatile platform for general contractors, agricultural use, and equipment hauling. A chassis cab, by contrast, is designed to carry specialized bodies—service, flatbed, stake, dump, utility crane, or box—while offering clean mounting points, PTO availability, and often higher payload thanks to purpose-built frames and rear suspensions. It also streamlines upfitting with standardized bolt patterns and wiring provisions.

Checklist: choosing your configuration:

– Duty cycle: daily mileage, idling time, expected engine hours, and average load per trip

– Terrain and climate: grades, altitude, heat, and cold influence powertrain and cooling needs

– Load type: dense materials vs. bulky cargo determine bed and body choices

– Trailer style: bumper-pull vs. fifth-wheel/gooseneck changes stability and tongue weight

– Traction: 4×2 for highway fleets; 4×4, locking differentials, and all-terrain tires for mud, snow, or job-site ruts

– Electrical: inverters, extra alternator output, upfitter switches, and dedicated power feeds

– PTO and hydraulics: required for certain service bodies, compressors, and cranes

– Visibility and safety: camera arrays, spotlights, mirrors, and trailer-specific sensors

– Ergonomics: seat durability, washable floors, storage solutions, and in-cab organization

Finally, think about serviceability and downtime. Are filters accessible? Can the upfit be removed or repaired without immobilizing the truck? Will your local shops stock wear items like brake pads and load-range E or F tires? Treat the spec sheet as a blueprint for uptime. The right 2500 or 3500, configured with the correct axle ratio, suspension, and hitch hardware, is more than adequate—it is tailored to your work, creating a margin of safety and productivity that pays back for years.

Performance, Durability, and Capability: What’s Under the Skin

Heavy-duty trucks succeed or fail based on how they manage heat, torque, and weight. Engine options split broadly into gasoline and turbo-diesel. Gas engines rev higher and are well-suited to stop-and-go, lighter-duty cycles, and shorter towing stints. Turbo-diesel engines deliver muscular torque right off idle, making them natural choices for frequent towing, high-altitude climbs, or work that demands extended low-speed pulling. Beyond raw power, the cooling stack—radiator, charge-air cooler, transmission cooler, and sometimes auxiliary coolers—determines how consistently the truck can hold a gear on a grade without overheating. Transmission programming matters too: tow/haul modes alter shift schedules, improve converter lockup, and collaborate with engine braking to maintain safe downhill speeds with less brake fade.

Brakes and suspension are the unsung heroes of heavy hauling. Larger rotors, multi-piston calipers, and fade-resistant pads, often paired with hydroboost systems, keep stopping distances predictable when grossing near GVWR. Many heavy-duty diesels add exhaust braking, which uses turbo and exhaust backpressure to slow the vehicle—a game-changer for long descents with heavy trailers. Leaf-spring rear suspensions carry the lion’s share of weight. Overload leaves, helper springs, and sway bars stiffen the platform under load, while air-assist systems can level the truck and reduce headlight aim issues. Tires complete the equation: load-range E or F ratings, reinforced sidewalls, and correct pressures (often 65–80 psi or higher when loaded) preserve handling and prevent overheating.

Traction systems protect progress on poor surfaces. Two-speed transfer cases provide low-range gearing for precise control. Mechanical locking differentials send power evenly to both wheels, while limited-slip units and electronic traction controls help when one side loses grip. Trailer stability programs use yaw sensors and selective braking to tame sway, and integrated trailer brake controllers match braking force to trailer weight. Camera views—bed, hitch, surround, and wide-angle rear—simplify connections and lane changes, especially with tall cargo blocking mirrors.

Durability depends on materials, coatings, and maintenance. Fully boxed frames with high-strength steel resist twist and support heavy upfits. Corrosion protection beneath the body and inside the frame rails helps in winter climates. Maintenance schedules vary, but oil changes in the 5,000–10,000-mile range for gasoline and longer intervals for certain diesels are common; fuel filter changes and water separators are critical for diesel longevity. Diesel particulate filters periodically regenerate; avoid excessive idling that prevents complete cycles. Expect DEF consumption roughly 2–3 percent of diesel fuel use by volume, and keep it fresh in cold climates. Finally, trust standardized capacity ratings such as SAE J2807 for a realistic baseline, but verify with your specific build and the ratings printed on your truck and hitch equipment.

Ownership Economics, Safety Tech, and a Decision-Focused Conclusion

Total cost of ownership blends purchase price with the long tail of fuel, maintenance, insurance, downtime, and resale. Entry-level work trims with gasoline engines often land in the lower-to-mid five-figure range, while heavily optioned diesel dual-rear-wheel models can reach the low six-figure territory. Fuel consumption is variable and not always rated by federal agencies for heavy-duty pickups. As a practical guide, many owners report gasoline models near 8–14 mpg unloaded and 6–10 mpg when towing sizable trailers. Comparable diesel models may see roughly 14–22 mpg unloaded and 9–14 mpg while towing, with terrain, speed, and wind making meaningful differences. Tires, brakes, and fluids add up; budget for premium, high-load tires and anticipate that aggressive job-site use can shorten replacement intervals.

Safety and driver assistance technologies reduce risk and fatigue. Useful features include forward collision warning with automatic braking, adaptive cruise control tuned for heavy loads, lane-keeping support, blind-spot monitoring calibrated for trailers, cross-traffic alerts, and hill-start or hill-descent assist. Trailer-centric aids such as integrated brake controllers, trailer tire-pressure monitoring, multiple camera views, and trailer length input can transform a long tow into a calmer experience. Training matters too—teach drivers how to distribute cargo, set tongue weight, manage tire pressures, and use engine braking on descents. Good habits often prevent the very problems people try to solve with bigger hardware.

Be mindful of compliance. Depending on GVWR, GCWR, and business use, you may encounter commercial-vehicle rules related to licensing, inspections, and hours of service. Requirements vary by jurisdiction, so consult local regulations before signing paperwork. Proper documentation and scale awareness prevent costly delays and fines, especially when operating near 10,001 pounds GVWR and beyond with commercial intent.

Decision checklist and closing guidance:

– If payload and pin weight drive the job, a 3500—especially with dual rear wheels—offers stability and margin

– If mixed daily driving and moderate towing dominate, a 2500 can provide capability without excess cost or size

– Choose diesel for frequent heavy towing, high altitude, and long service cycles; pick gasoline for lower upfront cost, lighter duty cycles, and simpler emissions maintenance

– Validate every claim with the door-sticker ratings, hitch labels, and SAE J2807-aligned numbers

– Test with real loads when possible, and use telematics to monitor idling, fuel burn, and maintenance timing

For contractors, ranchers, and fleet managers, the right heavy-duty pickup is a productivity multiplier. Start with honest load data, spec conservatively, and prioritize safety systems that reduce fatigue. Whether you land on a 2500 for balanced versatility or a 3500 for greater payload and towing headroom, the goal is the same: choose a configuration that fits your work on its hardest day, not its easiest. Do that, and the truck becomes a reliable partner that pays back every mile.